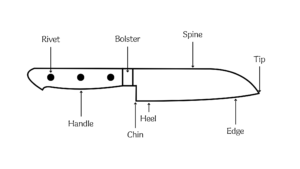

Double-edged

Double-edged blades have a symmetrical structure with both sides ground at the same angle. The most significant feature is that the blade does not veer to either side and moves straight through the food, making the cutting direction easy to stabilize.

This structure originated with Western knives like the Gyuto, which were introduced alongside Western culture. While mono-steel construction using a single material was common for Western knives at that time, many products are now manufactured using a laminated “Awase” structure, where hard steel is sandwiched between layers of soft steel, utilizing Japanese forge-welding techniques.

Because the blade moves straight and is easy to handle, it is widely used for highly versatile knives not limited to specific tasks, such as Santoku and Petty knives.

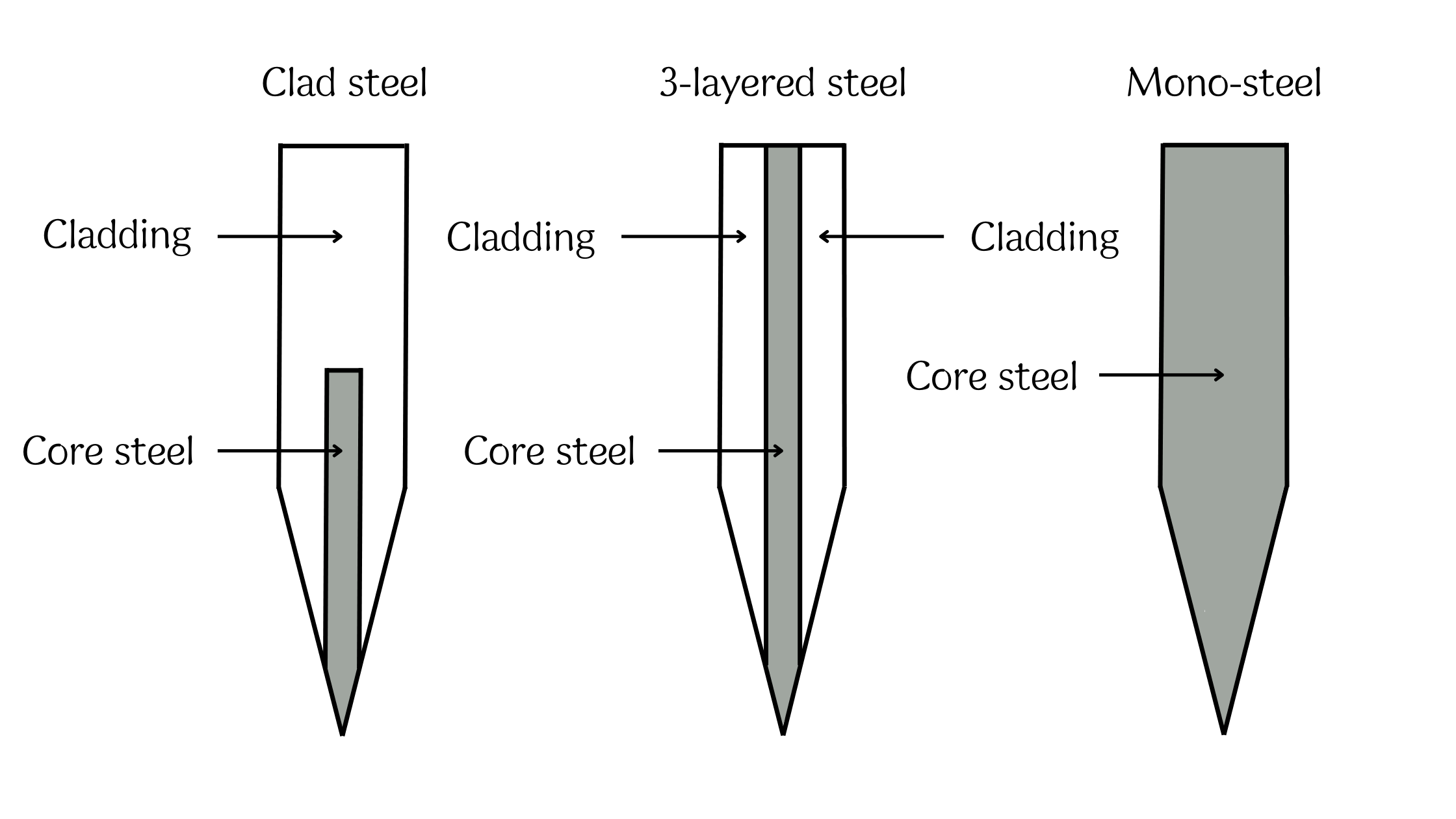

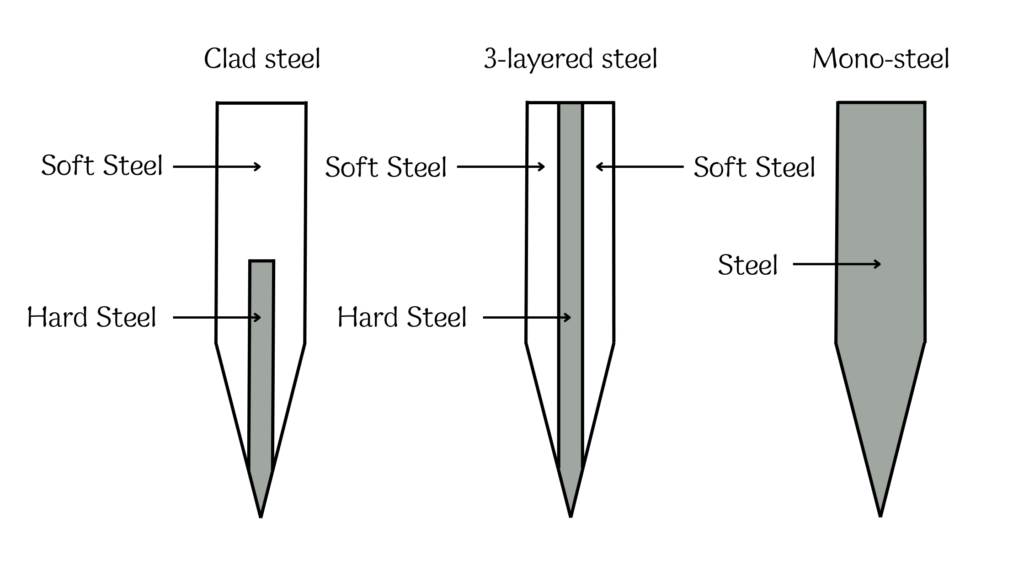

Structure and Characteristics of Laminated Blades (Awase)

This structure consists of a hard steel core sandwiched between layers of soft steel from both sides. Since the sides are made of soft steel, it has the advantage of making the process of grinding down the thickness of the sides smoother compared to mono-steel blades.

Currently, clad materials, which have the hard steel and soft steel pre-joined, are the mainstream. By skipping the forge-welding process by craftsmen, manufacturing costs are reduced, allowing for the stable provision of knives with consistent quality.

Warikomi

This structure involves making a cut in the center of the base metal and inserting steel into it. Unlike three-layer steel, the spine is encased in the base metal, and the steel is exposed only at the cutting edge.

Three-layer Steel

This structure features the core steel being completely sandwiched between the base metal from both sides. Unlike Warikomi, the difference in appearance is that the core steel is exposed all the way to the spine.

Structure and Characteristics of Mono-steel Blades (Zenko)

A key feature is that it consists of only a single material. Unlike laminated knives (Warikomi or Three-layer steel), the material does not change as you continue to sharpen it.

Since the entire blade is made of hard steel, reducing the thickness of the sides takes more time, but it offers the flexibility to adjust the blade shape without having to consider the boundary with the base metal.

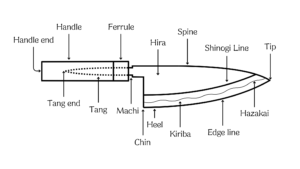

Single-edged (Kataba)

Single-edged is a structure mainly found in Japanese knives where only one side of the blade is angled.

The most significant feature is that the blade enters diagonally when cutting, and the sliced food separates easily from the blade. Additionally, the back side has a concave shape called “Urasuki,” a structure designed to reduce friction with the food.

This is common in knives specialized for specific tasks, such as Deba or Yanagiba, and is suitable for work requiring beauty and thinness of the cross-section, such as slicing sashimi or peeling vegetables.

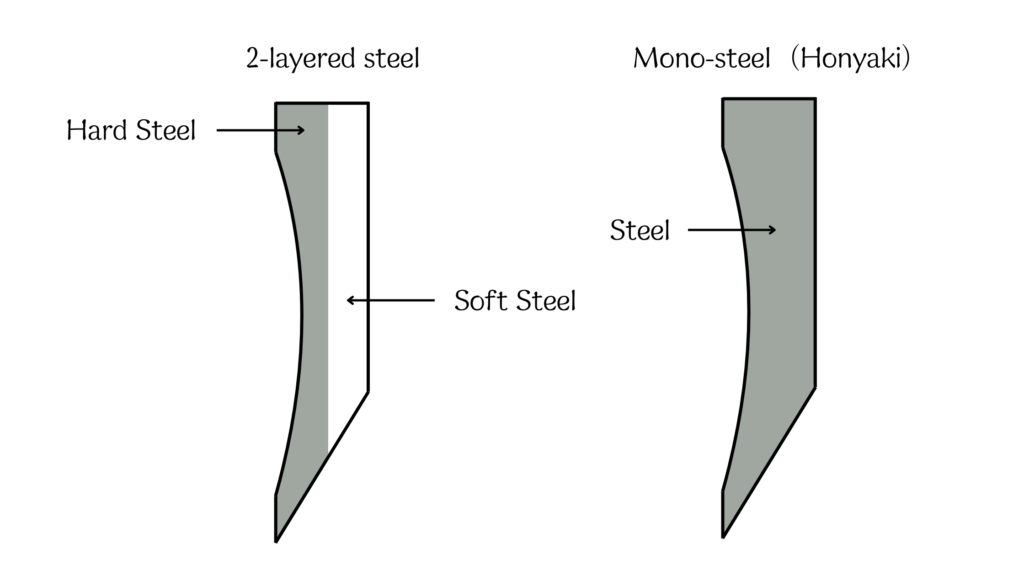

There are two types of structures: “Nimai-awase,” which consists of steel and soft metal bonded together, and “Honyaki (Zenko),” which consists of a single steel material.

Structure and Characteristics of Laminated Blades (Awase)

It is a “two-layer” structure in which hard steel and soft base metal are bonded together.

Since the base metal, which makes up most of the side, is soft, it has the advantage of making the sharpening process smoother and less burdensome compared to “Honyaki,” which is hard throughout.

Because metals with different thermal expansion rates are joined, there is a risk of warping or distortion. Currently, production using clad materials is becoming widespread, in addition to traditional forge-welding.

Structure and Characteristics of Honyaki

This structure consists of a single piece of steel, forged from a single steel bar similar to a Japanese sword.

By applying clay coating during the quenching process to create temperature differences in different parts, it becomes easier to adjust distortion after quenching. As a result, the prominent visual feature is the beautiful hamon that appears, much like a Japanese sword.

Because the entire blade is extremely hard, it is possible to create a sharp edge; however, since it lacks flexibility, it is prone to breaking or chipping upon impact. With no soft base metal, sharpening requires advanced skill and significant time, positioning these as rare, high-end knives finished with great care by craftsmen.

However, since the surface of a “Honyaki” is uniform and extremely smooth, surface tension from the food’s moisture acts to maximize suction. This suction resistance is said to destroy the food’s cells, causing moisture to leak out or having other negative effects compared to “Awase” knives.

While they are often traded at high prices and said to offer the best sharpness, an “Awase” knife is often the better choice, so a “Honyaki” is not necessarily the superior knife. They are ultimately valued as traditional crafts. It is important to understand the structure and mechanism of each and choose a knife based on your purpose and sharpening technique.